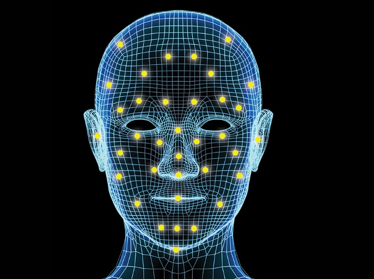

The revolutionary technology of 3D Sensing And Imaging is fundamentally changing how machines perceive and interact with the physical world. Unlike traditional 2D cameras that capture a flat image, this advanced technology enables devices to measure depth and capture the three-dimensional shape and appearance of objects and their surroundings. By creating a detailed "point cloud" or depth map of a scene, it provides the crucial spatial context that allows for a much richer and more accurate digital representation of reality. This ability to "see" in three dimensions is the foundational technology that is unlocking a new wave of innovation, from secure facial recognition on our smartphones to the navigational systems of autonomous vehicles and the immersive worlds of augmented reality.

The technology behind 3D sensing and imaging is diverse, with several key methods being used to achieve depth perception. One of the most common is stereoscopic vision, which mimics human sight by using two cameras to calculate depth from the slight differences in their perspectives. Another prominent technique is structured light, where a known pattern of infrared light is projected onto a scene, and a sensor measures how the pattern is distorted by the objects it hits to calculate their shape and distance. A third major approach is Time-of-Flight (ToF), which works by emitting a pulse of light and measuring the precise time it takes for the light to bounce off an object and return to the sensor, thereby determining its distance with incredible accuracy and speed.

The applications of this powerful technology are as vast as they are transformative, spanning across a multitude of industries. In consumer electronics, it is the enabling technology for features like facial authentication and advanced photographic effects like "portrait mode." In the automotive sector, LiDAR (a form of ToF) is a critical sensor for self-driving cars, providing a detailed, 360-degree view of the vehicle's environment. In manufacturing, 3D imaging is used for quality control and inspection, allowing for the precise measurement of components with microscopic accuracy. In healthcare, it is used for everything from creating custom prosthetics to assisting with robotic surgery, showcasing its incredible versatility and profound impact on modern technology.